Detailed introduction PET preform mold

In our daily life, preform molds are widely used in multiple packaging industries such as edible oil, beverages, candy, and medicine etc.

I、The concept of preform mold

PET preform mold is a molding method that uses an injection machine to inject molten material into the mold to make a shape, and then puts the parison into the blow mold while it is hot, and introduces air to inflate the parison.

II、Components of preform mold

The injection mold is mainly composed of three parts: pouring system, molded parts and structural parts. Among them, the pouring system and molded parts are the parts that are in direct contact with the plastic. They are the most complex, most changing parts of the mold and require the highest processing accuracy.

III、Principle of preform mold

The powdery or granular plastic is fed from the hopper of the injection machine into the heated barrel; after heating, melting and plasticizing, the material will be compressed and moved forward with the help of the thrust of the plunger or screw, passing through the nozzle at the front end of the barrel. It is injected into the closed mold cavity with a relatively low temperature at a very fast speed; after a certain period of cooling and shaping, the mold is opened to obtain the product.

IV、Advantages of preform molds

PET preforms will largely determine the quality of plastic bottles, and their importance to plastic bottles is self-evident. The functions of an injection molding machine mainly include: being able to install a mold of a given size, providing sufficient mold clamping force, operating according to cycle time requirements, plasticizing enough materials, etc.

V、Several aspects that need to be noted when choosing a preform mold

1.Product weight: Products of different weights have different requirements for hot runner.

2.Cycle time: Rapid production cycle means that the requirements for nozzles will be very high.

3.Gate: In order to maintain a good thermal balance in each molding cycle, the hot flow nozzle tip must have the functions of melting materials and cooling and sealing.

4.Nozzles: Nozzles can be distinguished by size, temperature distribution, physical properties, materials used, ease of maintenance, price, etc.

5.Runner: The use of hot runner system not only saves raw materials, but also eliminates the previous process of removing material handles by hand, machinery or other methods.

6.Product design: In order to ensure a smooth product appearance at the end of molding, those factors must be considered in its structural design.

7.Temperature control: Each nozzle must be connected to a relatively complex temperature controller.

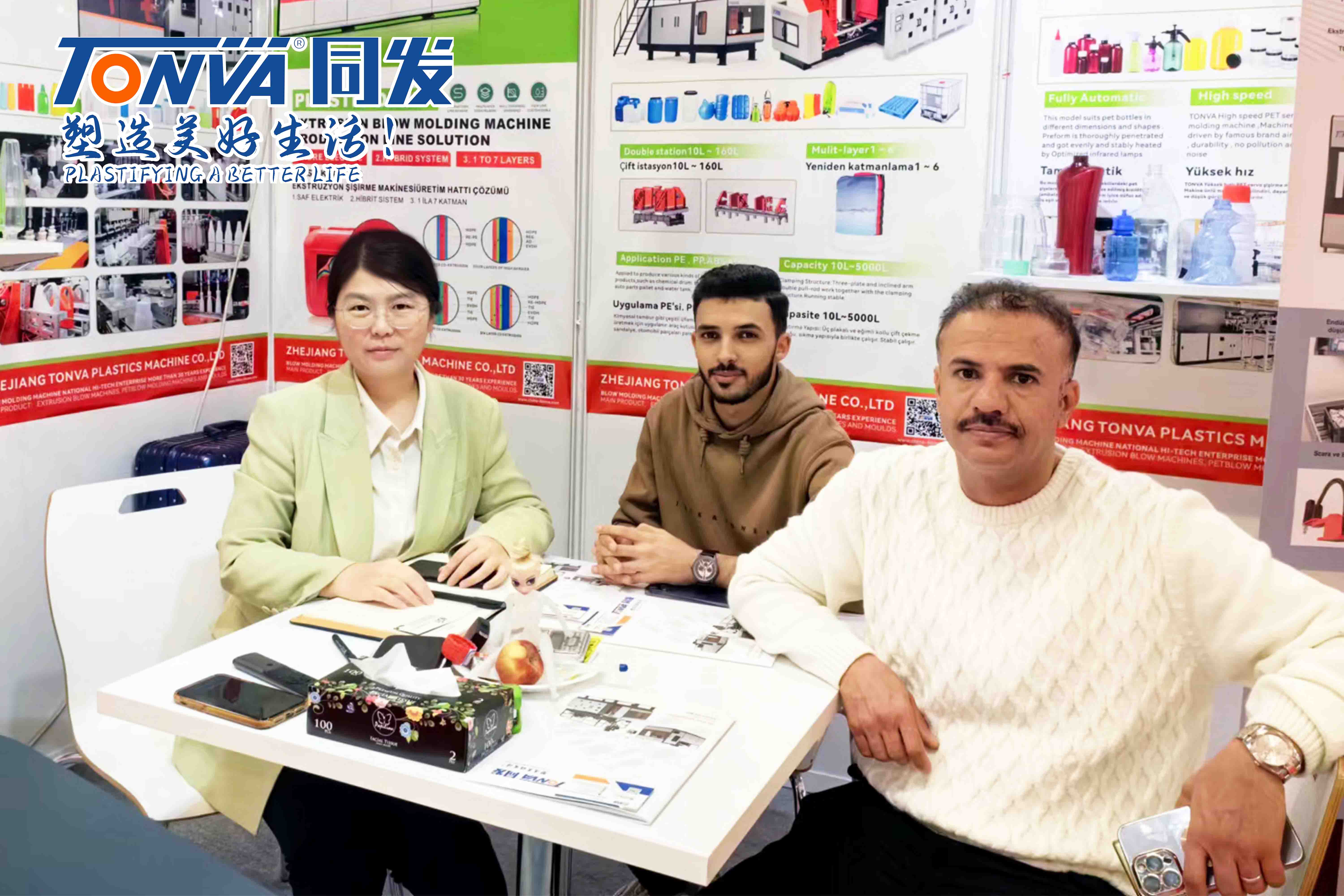

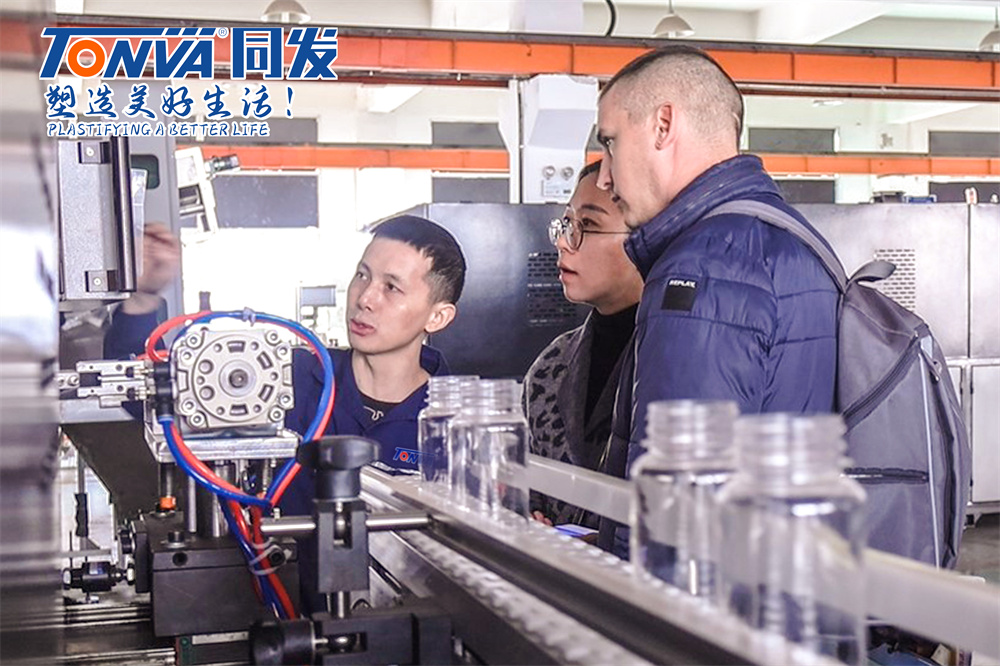

Zhejiang TONVA Plastics Machine Co., Ltd is a company specializing in the development and production of bottle preform molds. It can customize water bottle preform molds, oil bottle preform molds, wide-mouth bottle preform molds, cosmetic bottle preform molds, and disinfection/hand sanitizer molds according to customer requirements. Bottle preform molds, can molds, etc., achieve stable quality, timely delivery, reasonable prices, and considerate service, so that customers can rest assured and satisfied.

TONVA follows the "quality of survival, innovation and development, market-oriented, service for the purpose" business philosophy, we are willing to WIN-WIN together and plastifying a better life with you!

Warmly welcome customers to call us to negotiate and come to visit and patronize!