PET pesticide bottle blowing machine

China encourages pesticide producers to use packaging that is easy to utilize resources and dispose of, water-soluble polymer packaging or packaging that is biodegradable in the environment, and gradually phase out aluminum foil packaging. Encourage the use of large-capacity packaging that is easily recyclable.Currently, pesticide packaging sold in the Chinese market is mainly made of four materials: glass, plastic, metal, and paper-plastic. Among plastic packaging, pesticide bottles made of PET have the highest recycling value.

So what kind of machine to produce PET pesticide bottles?

PET pesticide bottle blowing machine is mainly used to produce PET pesticide bottles. There are one-step bottle blowing machine and two-step bottle blowing machine. The investment cost of one-step bottle blowing machine is several times higher than that of the two-step method. Below I will focus on the two-step method. Method bottle blowing machine, two-step bottle blowing machine can choose semi-automatic stretch bottle blowing machine and fully automatic stretch bottle blowing machine.

The semi-automatic blow molding machine requires one person to place the preforms in the heating zone for heating and then put them into the blow molding equipment. A 2-cavity semi-automatic blow molding machine can produce about 700-900 bottles per hour for a 500ml bottle. Semi-automatic bottle blowing machines have low output, high labor costs,

and improper operation may cause safety hazards.

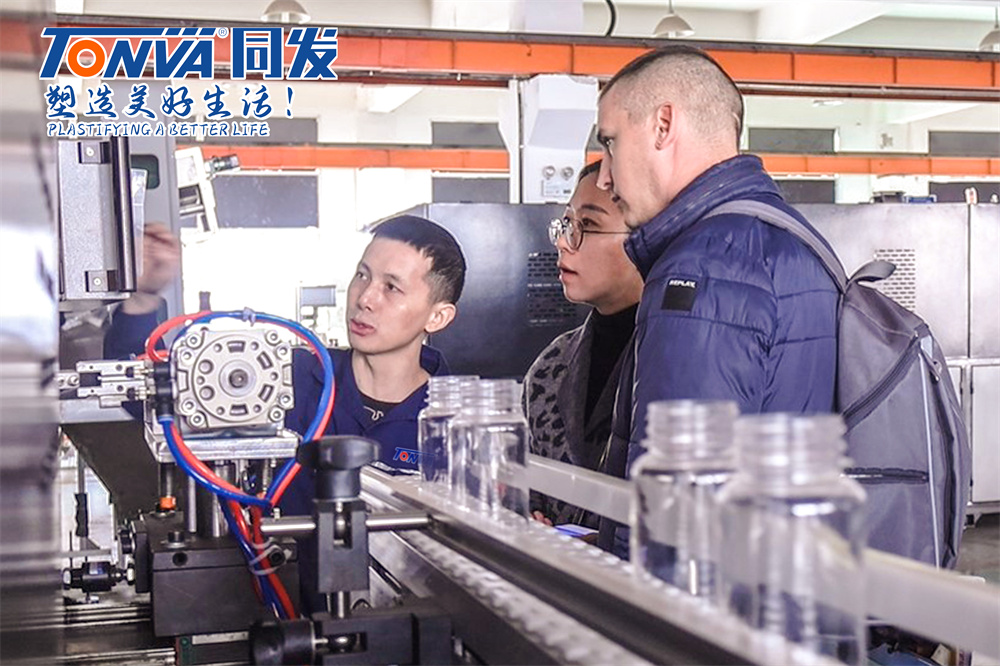

The fully automatic PET bottle blowing machine is equipped with a mechanical air claw, which can fully realize automatic embryo insertion and automatic bottle discharge without manual operation. Compared with semi-automatic bottle blowing machines, it is safer and saves labor costs. The fully automatic bottle blowing machine needs to produce the largest bottle capacity according to the diameter of the bottle, and select the model for the hourly output, such as 2-cavity, 3-cavity, 4-cavity, 5-cavity, 6-cavity and other models with an output of about 2,000 to 7,000 bottles per hour. The output of the pesticide bottle machine is mainly affected by the bottle capacity, shape and weight.

In addition to the pesticide bottle blowing machine, a complete set of equipment also requires auxiliary equipment such as preform loader, bottle leakage detector and packing machine.

Zhejiang TONVA Plastics Machine Co., Ltd has designed and produced pesticide bottles for many domestic and foreign companies, and has won unanimous praise from customers. Welcome to call us and we will provide you with a one-stop solution for free.